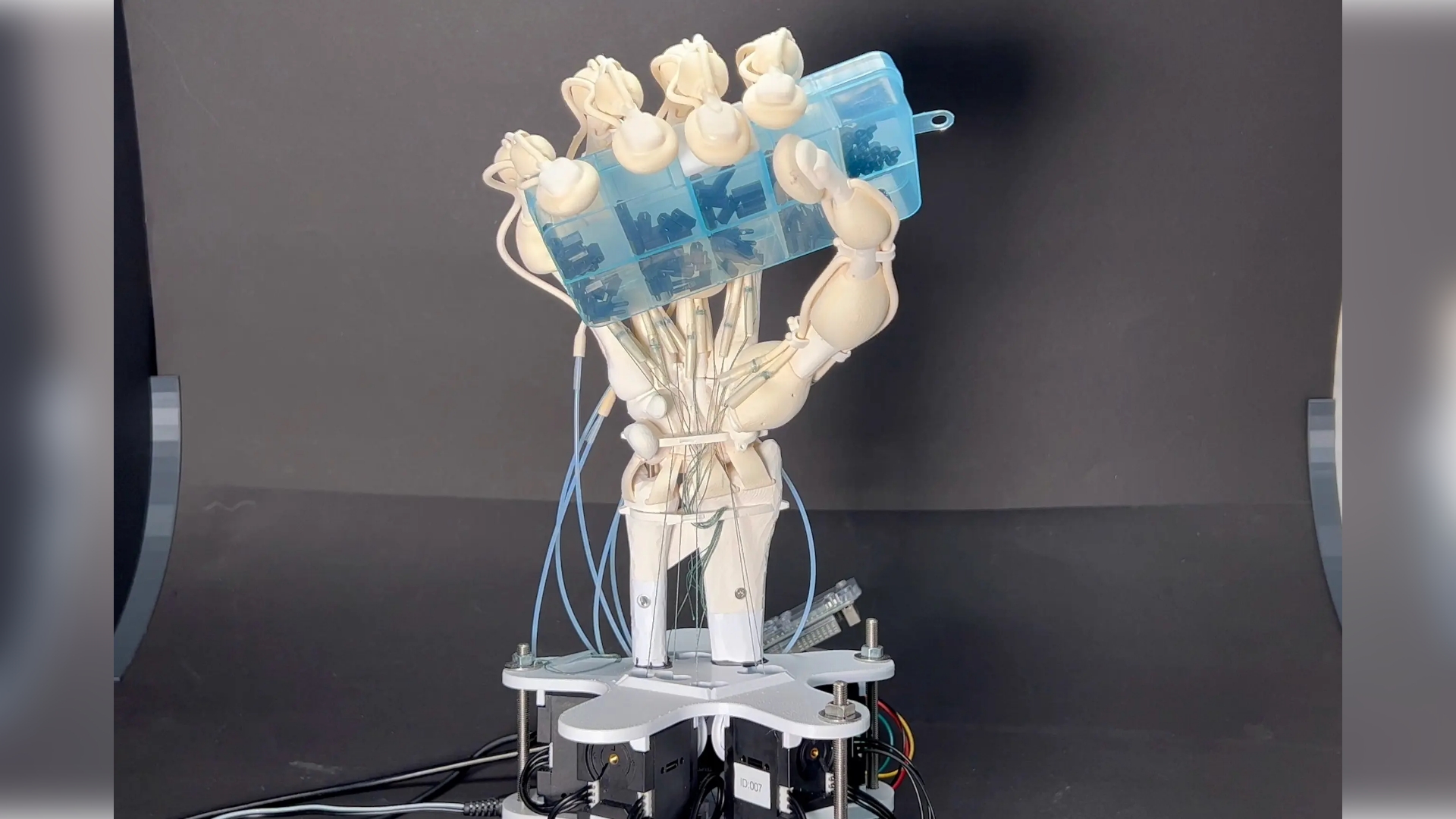

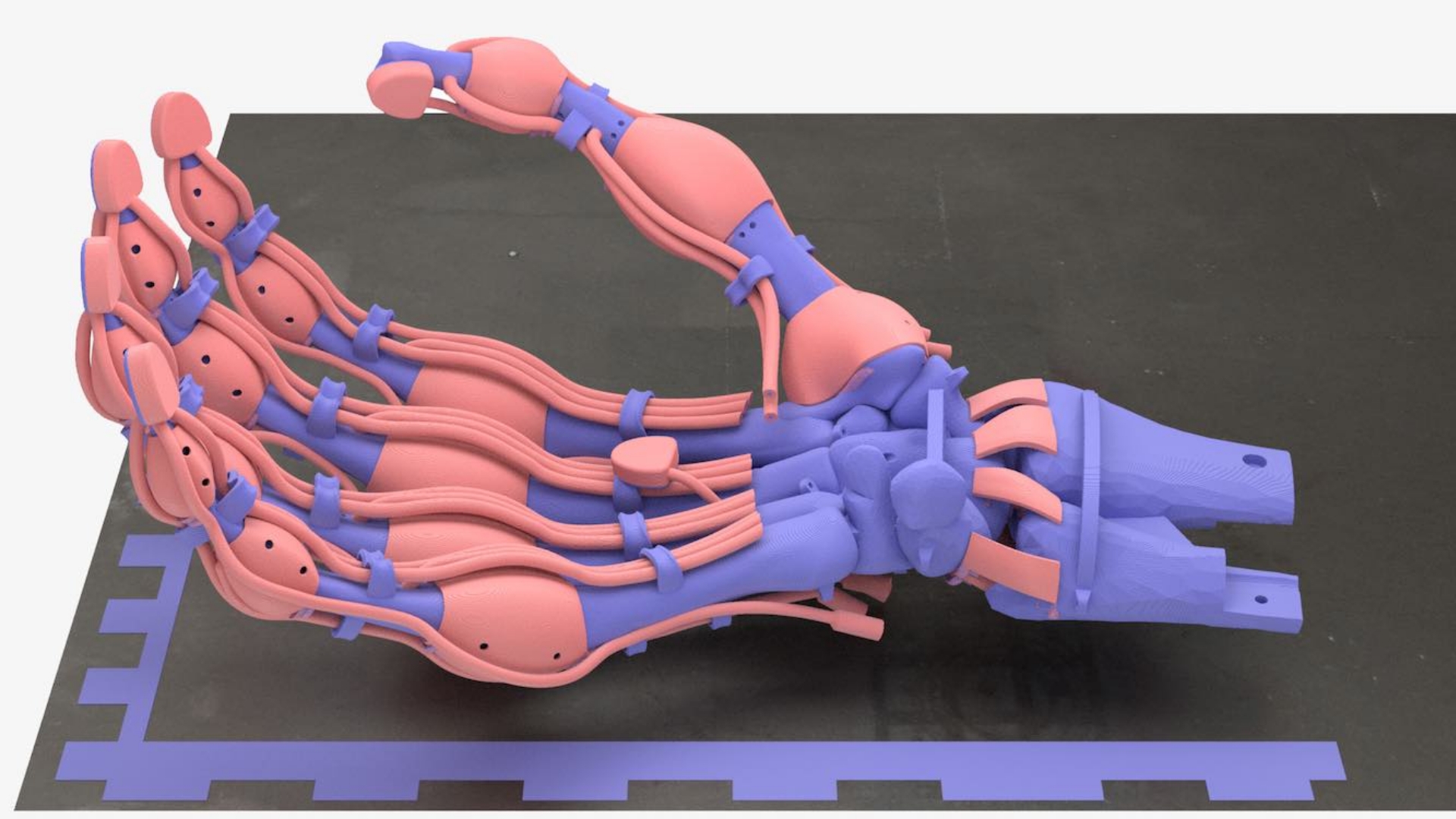

A robotic hand including bones, ligaments, and tendons was created by scientists using 3D printing.

3D printing technology is broadening its material options, including slow-curing polymers with improved elastic characteristics and durability.

This new approach allows researchers to 3D print complex, durable robots from a variety of high-quality materials, combine soft, elastic, and rigid materials, and make delicate structures with cavities.

“We wouldn’t have been able to make this hand with the fast-curing polyacrylates we’ve been using in 3D printing so far,” says Thomas Buchner, a doctoral student in the group of ETH Zurich robotics professor Robert Katzschmann and first author of the study published in Nature.

“We’re now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

ETH Zurich researchers created a 3D printing process that uses thiolene polymers for the elastic ligaments of robotic hands. This method enables the stiffness of thiolenes to be fine-tuned to fit the requirements of soft robots, making them safer to work with humans and better suited to handling fragile objects. A 3D laser scanner is used to verify each printed layer for surface abnormalities, and a feedback mechanism is used to adjust for these inconsistencies. The researchers intend to use the technique to investigate more possibilities and construct more complex structures.